An air washer is used to condition the air primarily in industrial plants, factories, DG rooms, basement/parking areas, commercial kitchens, and sometimes in office buildings as well. Since chiller based cooling, ductable ac, and VRF / VRV solutions are expensive, therefore, in certain specific cases, an air washer unit is used to condition the air.

Air washer working principle

Air washer is also known as an evaporative air cooler because it follows the principles of evaporative cooling (also termed as adiabatic cooling). As the name suggests, the atmospheric air is cooled down to pleasant temperature by passing it through a stream of evaporative water. Therefore, in a nutshell, the water acts as the cooling agent in an air washer. The water shall be constantly replenished in a typical air washer unit. The water is generally kept cold through a combination of pads and when incoming atmospheric hot air passes through the unit, the air loses heat that in turn evaporates the water. The outgoing cool air now is distributed by a blower to the various parts of a building through duct lines. This is a standard direct evaporative cooling.

There is however an alternative to the direct evaporative cooling and that process is known as indirect evaporative cooling. In indirect evaporative cooling a heat exchanger is used to remove heat from the incoming hot air by letting this incoming air pass through the cold secondary air stream across the walls of the heat exchanger. In other words, the two air streams do not mix. Therefore, in indirect evaporative cooling, the cooler air is distributed to the various parts of a building without increasing the humidity of the outgoing cool air. This is the prime difference between a direct evaporative cooling and an indirect evaporative cooling.

If an air washer unit adopts either the direct or indirect evaporative cooling approach, then, that unit is termed as a single-stage air washer unit. However, when the above two kinds of cooling approaches are used simultaneously, then that unit is known as a two-stage air washer unit. In a two-stage air washer unit, the first stage is that of the indirect evaporative cooling followed by the second stage of direct evaporative cooling. Two-stage air washer unit can cool the air to much lower temperature than is possible in a single-stage air washer unit.

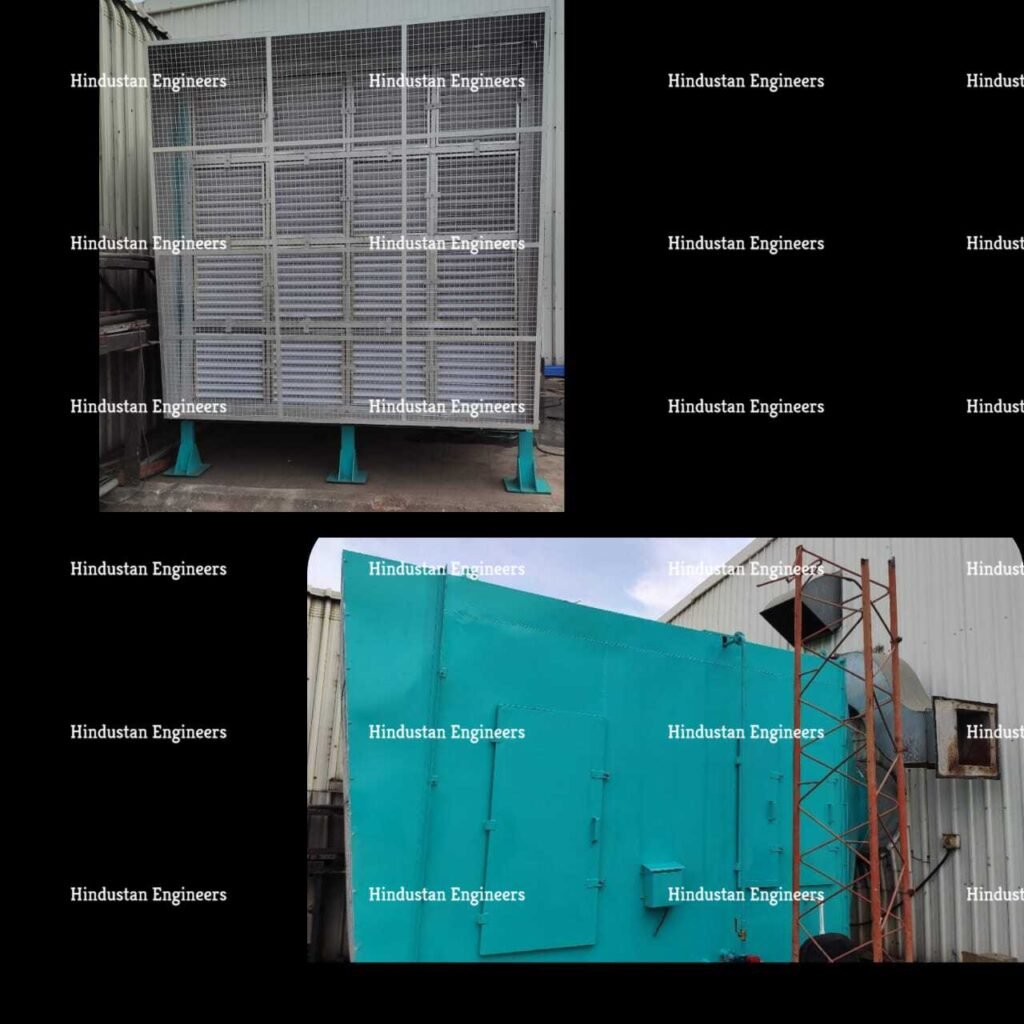

Typical configuration of a standard Air washer in India

In the marketplace, 1000 CFM (Cubic Feet per Minute) to 100000 CFM of air washer units are commonly used. Based on the HVAC design, the appropriate CFM (airflow) of air washer shall be installed. A typical air washer comprises outer skin and inner skin. The outer skin is made of 0.6 mm pre-coated GI, whereas the inner skin is made of 0.6 mm plain GI. Hollow extruded Aluminum profile is used for the framework. The sump is made of 18 gauge SS 304. And the unit base is generally based on G.S.S. Synthetic (non woven type) filters are used with an efficiency of about 90% down to 10 micron. In addition, the cellulose pads are used along with the eliminator that is made from the PVC. The airflow volume in CFM and the desired static pressure in mm wg determine the choice of the fan and the power rating of the motor. The higher the airflow volume in CFM and static pressure in mm wg, the higher the fan diameter and motor rating. Sometimes, instead of using a one large diameter fan, two smaller diameter fans can be used to achieve the same airflow volume and static pressure. A DIDW backward curved fan is typically used in the air washer units. However, ongoing research and development and emphasis on energy-efficiency mean that EC fans are being used widely in the development of air washer units.

As an end user, one should be looking for the supply, installation and testing of “Package” type Evaporative air washer comprising of DIDW GI epoxy coated fan (Backward / forward curved), complete with base frame, double skin casing made out of 24G (or 0.63 mm GI sheet) powder coated galvanized sheet having flanged and bolted panels insulated with TF quality expanded polystyrene. The wet section & tank should be made of 2 mm thick SS. The Air-washers shall be complete with fill of calculated depth & face velocity across the fill shall be limited to the calculated RPM. The complete Air-washer shall have an adiabatic efficiency of 90% & shall be complete with motor, belt, drive package, GI B-Class interconnecting piping aluminum viscous filter, float valve, quick fill, overflow and drain connection, spray headers, strainer of wire-mesh brass screen etc. The Air-washer shall be complete with 1 Nos. water circulation pumps including one No. stand by pump. The pump / motor should have a suitable protection cover. The static pressure in mm (WG) should be calculated beforehand keeping in mind the capacity to deliver CFM at 90% adiabatic efficiency of the evaporative medium.